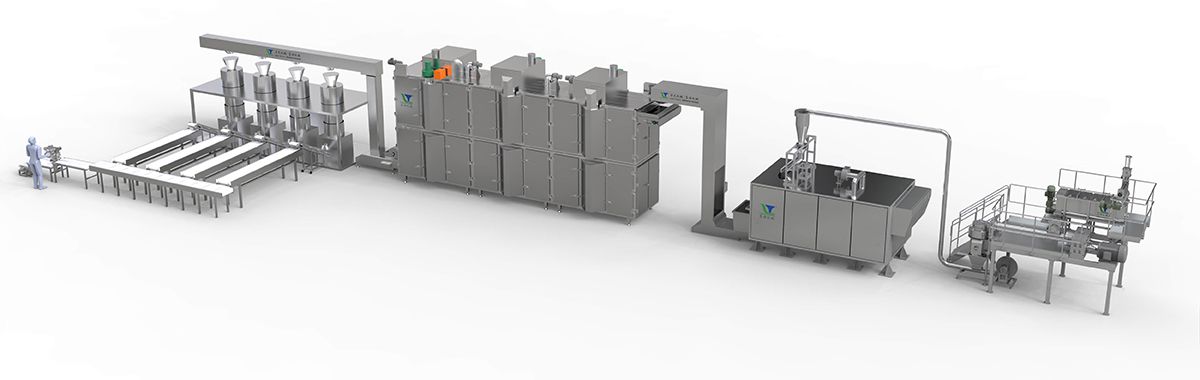

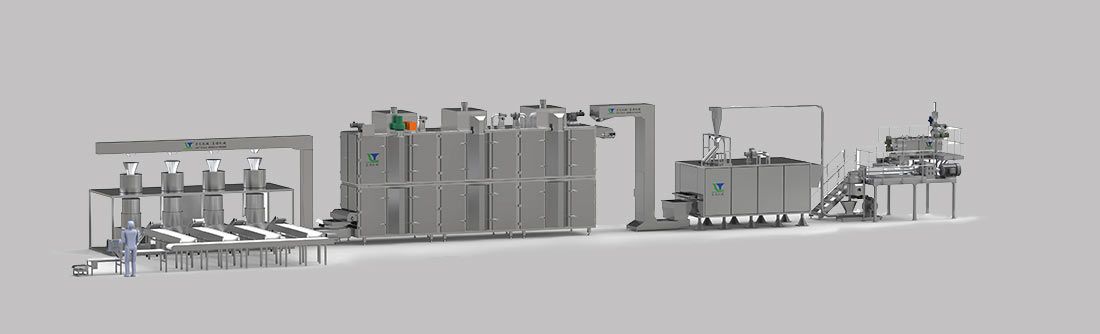

Short-cut macaroni and pasta production line are specially designed for short-cut macaroni and pasta. This production line consists of different processing equipment with specialized techniques, including a feeding system, extruding system, cutting system, vibration pre-dryer, dryer, and cooler. It adopts a continuous industrial production design, providing automatic processes from the input of raw materials to the packaging of macaroni. With the highly automated system, this macaroni and pasta production line is easy to operate and always delivers high-quality finished products of diverse shapes.

- This production line can produce macaroni and pasta with diverse specifications to meet the different needs of customers. The output of a single line ranges from 150 kg to 1000 kg per hour.

- Only a handful of workers are required, which greatly reduces labor costs.

- Smooth and stable running performance and low failure rate. The structure design of the production line is scientific and reasonable, and all spare parts and accessories are from domestic or international famous brands. It is equipped with automatic detection sensors, which can monitor the operation of important processes in real-time and ensure the traceability of products.

- The inner and outer parts of all machines are made of SUS304 stainless steel, the inner wall of the extruder sleeve is made of SUS304 stainless steel, and the extrusion screw is made of alloy steel. The whole machine can be cleaned with water. All pipelines are quick-connect, easy to disassemble and clean.

- High degree of automation. This line replaces traditional electric devices such as buttons, temperature control meters, frequency meters, and potentiometers with PLC and touch screen, and adopts a man-machine interface equipped with Ethernet switches to issue commands to realize information exchange and control.

The dry pasta processing line is specifically designed for short-cut pasta. This production line includes different processes, and each process has specialized techniques.

- Feeding and Extrusion machines

The paddles slowly rotate in the mixing tank to mix the material until optimal hydration is achieved, allowing the gluten matrix to form. The whole process from feeding to extrusion takes place under a vacuum at a temperature of 40-45°C. - Cutting machine

This machine is suitable for cutting all types of short-cut pasta, equipped with an automatic centering/positioning system for the cutting discs. - Vibrant pre-dryer

The surface of the Pasta is dried by hot and dry air to prevent sticking, raising its temperature to 70°C. - dryer

After pre-drying, the pasta is sent to the dryer to remove its moisture. The stable temperature is 77°C and the average drying time is 120-145 minutes. - Cooler

This automatic air cooling unit can lower the temperature of the pasta to 20-25°C and prepare it for packaging.

We can provide solutions tailored to your specific needs.