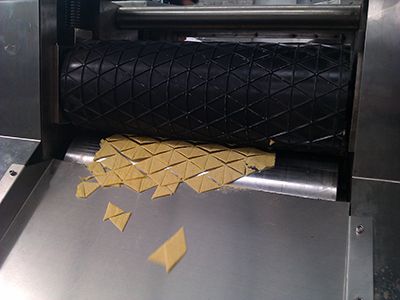

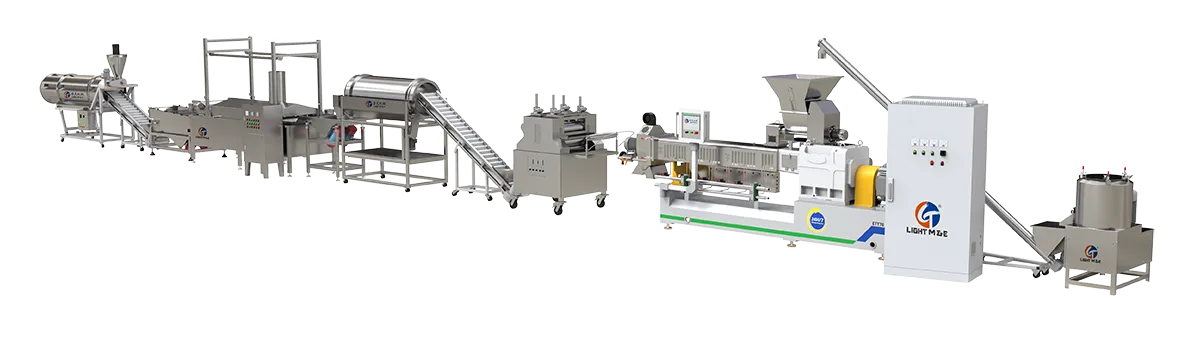

Doritos Tortilla Corn Chips Process Line is a new technology that replaces the traditional production by twin-screw extrusion technology. The production line including mixing materials, Extruding, Forming, Frying, Deoiling, Flavoring and Packing. No need boiler, and the production process is simplified, efficient, environmentally friendly and low-carbon. The final chips shape can be various by changing the roller on forming machine , such as triangles doritos, square corrugated chips, sticks, bugles, moon, fish, strips, diamond chips, Hexagon chips etc.

The raw materials can be most of grains flour, like corn flour, wheat flour, rice flour, buckWheat flour etc. By adding some pea flour, beans flour, it can also produce popular protein chips.

| Model | Main Drive Power | Output | Size (L*W*H) |

| ETT65 | 55kW | 200-600kg/h | 24000x1500x2200mm |

| ETT78 | 75/90kW | 300-1000kg/h | 23000x1500x2800mm |

| ETT98 | 200/250kW | 800-2500kg/h | 27000x1500x2800mm |

| SLT70H | 37/45kW | 100-300kg/h | 24000x1500x2200mm |

| SLT85 | 75kW | 400-700kg/h | 23000x1500x2300mm |

- Double Screw Extruder Equipped with Unique barrel and modular screw design, European standard design and materials, PLC control system, ensure the production much easier and convenient.

- Raw materials mainly grain powder, like corn flour, wheat flour, rice flour, oat meal, etc.

- Automatic Continuous Fryer with oil circulation system, automatic feeding new oil, oil filtration system, automatic cleaning the oil on-line. Frying time and temperature adjustable for different products.

- Several Capacity Solution Optional, from 200kg/hour to 2000kg/hour.

- Flour Mixer

- Screw Conveyor

- Double Screw Extruder

- Roller Cutting Machine

- Hoister

- Separating Drum

- Vibrate Feeder

- Continuous Fryer

- Vibrate De-oil Machine

- Flavoring Line

At present, our main business is research and development, production, marketing of all types of extruded food machinery and backing snack machinery. We are trusted and supported by many purchasers at home and abroad as a result of high quality of equipment, perfect customer service and good reputation. If these products are required by you, don't hesitate to contact us. We are the one you need!

We can provide solutions tailored to your specific needs.