Our Equipment

Nutrition rice powder equipment uses rice, corn, beans and all kinds of grist as raw materials to produce the rice powder. Through extruding and inflating, drying, crushing and mixing, nutrition rice powder machine could produce all kinds of nutrition powder, such as infant rice flour, sesame paste, and beans powder and so on.

This nutrition rice powder machine could finish all the process automatically from the feeding to the end. It has features of easy operation, without leak of rice powder, sanitation, energy conservation and convenient material feeding, etc.

Specifications

| Model | Main drive power | Output | Size(L×W×H) | Applied products |

|

ETT65

|

55kW | 150-400kg/h | 4300*950*1800mm | infant rice flour, sesame paste, and bean powder |

|

ETT78

|

75/90kW | 300-900kg/h | 4700*1000*1700mm | |

|

ETT98

|

200/250kW | 800-1600kg/h | 6500*1500*1800mm |

Features

- FT Series uses the Modular Circular Groove Screws ,Combination screw, made of high strength and durable hard alloy steel, can make different type products by combination screw; longer using time; different thread and shear section connection seamless; evolvent type spline housing, strong bearing and high assembling accuracy;

- Much Longer Using Life of Excellent Modular Screws and Square Barrels:Different Heating Sources Options and Low Maintenance charge: Square shape barrel, harden alloy bushing inserted wear-resistant,Locating pin connection, Machining accuracy high; The outer heating ring of the barrel has an independent aluminum silicate insulation layer to avoid heat loss and waste.

- Stable Performance and Longer Using Life guaranteed by Top Grade Gear Box and Bearings.Distribution box including automatic lubricating system, filtration system and cooling system; Automatic lubricating, filtration and cooling system, guarantee no opening the bear box within 3 years, 20 years using lifetime; high machining accuracy and loading big power;

- PLC Touch Screen, Max. Optimized control system, friendly HMI system, more data storage.

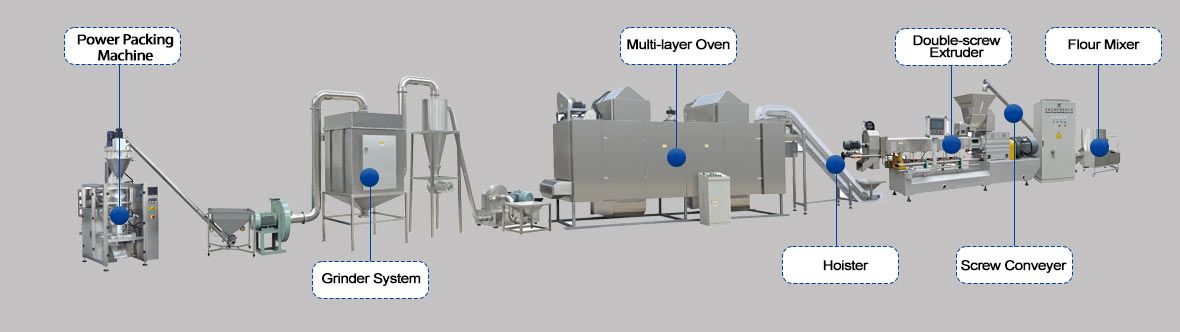

Flow Chart

- Flour Mixer

- Screw Conveyor

- Double Screw Extruder

- Conveyor

- Multi-layer Dryer

- Automatic Grinding System with Dust-collector

- Nutrients Mixer

- Powder Packaging Machine

Our machinery design department and technology department are comprised of experienced engineers and food production equipment designers. LIGHT food processing machinery, animal food machinery, food extruders, etc. are used widely in the field of food processing, and we also provide customers with total food-production and processing solutions. We take pride in our ability to provide newer, better equipment to our customers to handle their ever changing needs.

Food Processing Line

Are you planning on making something tasty and visually attractive?

We can provide solutions tailored to your specific needs.

Contact Us