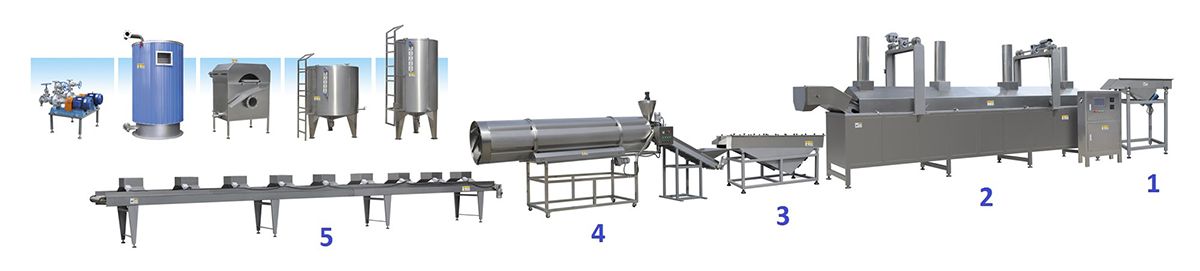

The continuous belt fried snack production line is specially designed for industrial use, including a feeding system, continuous frying system, de-oiling system, flavoring system and cooling system.

So it is fully automatic with high capacity and continuous process, which can avoid any workers mistake, and get the perfect fried food more precisely and efficiently It has wide applications, like puffed snacks, extruded pellets, dough snacks, beans, nuts, fresh vegetables, onions, potato chips, banana chips, plantain chips etc. For different food, we will apply either single-belt or double-belt fryers.

And we also provide auxiliary machinery or services, like oil tanks, pumps, oil filters, pipes and programs etc, they will help to monitor the oil level, feed oil automatically, and filter oil, so as to save much more production cost.

| Model | Drive Power | Heating temperature | Output | Dimensions | Products |

LTCF-300 | 4.3w | <250℃ | 100-300kg/h | 13100*1200*3500mm | Half-puffed snacks, extruded 2D/3D pellets, dough snacks, beans, nuts, fresh vegetables, onions, potato chips, banana chips, plantain chips, etc. |

LTCF-400 | 4.3w | <250℃ | 300-500kg/h | 16300*1200*3500mm | |

LTCF-500 | 4.9w | <250℃ | 500-800kg/h | 21500*1200*3500mm | |

LTCF-650 | 6.85kW | <250℃ | 800-1000kg/h | 25100*1500*3800mm | |

LTCF-800 | 10kW | <250℃ | 1000-1300kg/h | 28300*1500*3800mm |

- Vibrant Feeder

- Continuous Belt Fryer

- Vibrant De-oilng Machine

- Single Drum Flavoring Machine

- Cooling Conveyor

We can provide solutions tailored to your specific needs.